|

Specification |

Details |

|

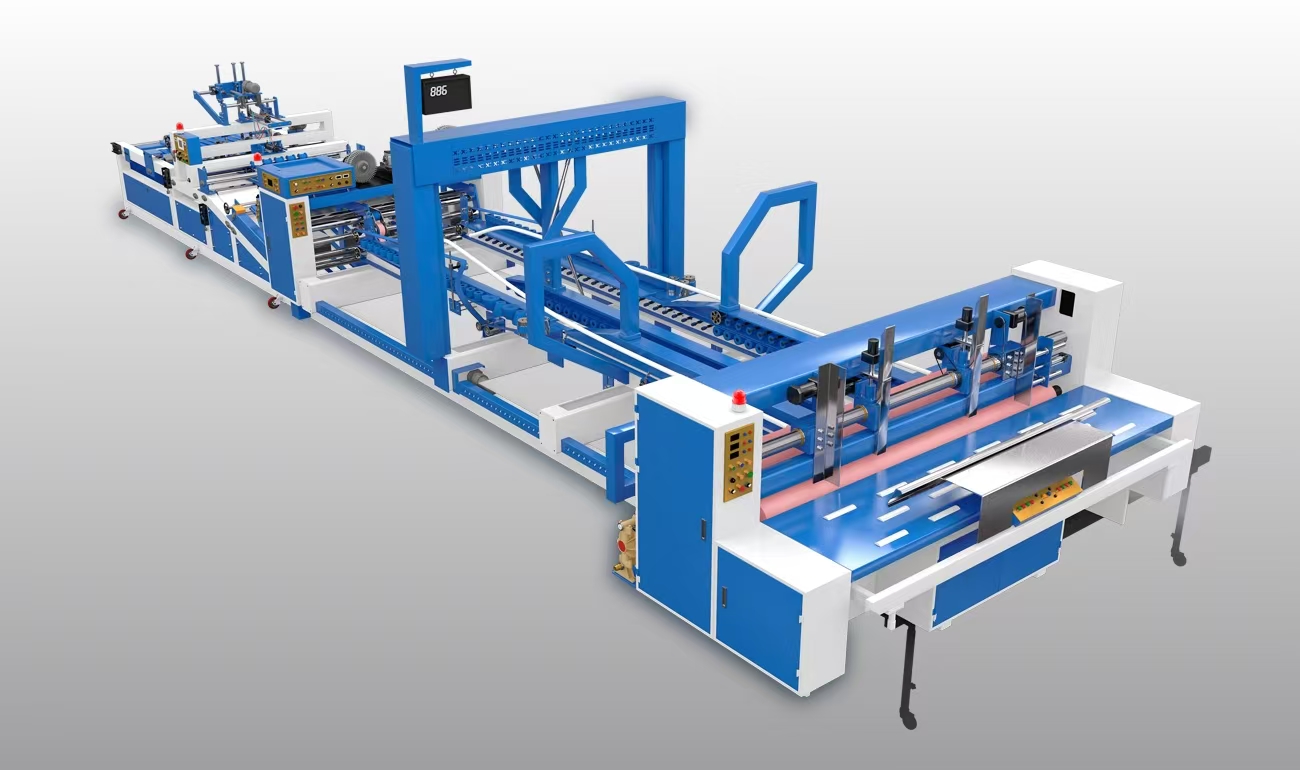

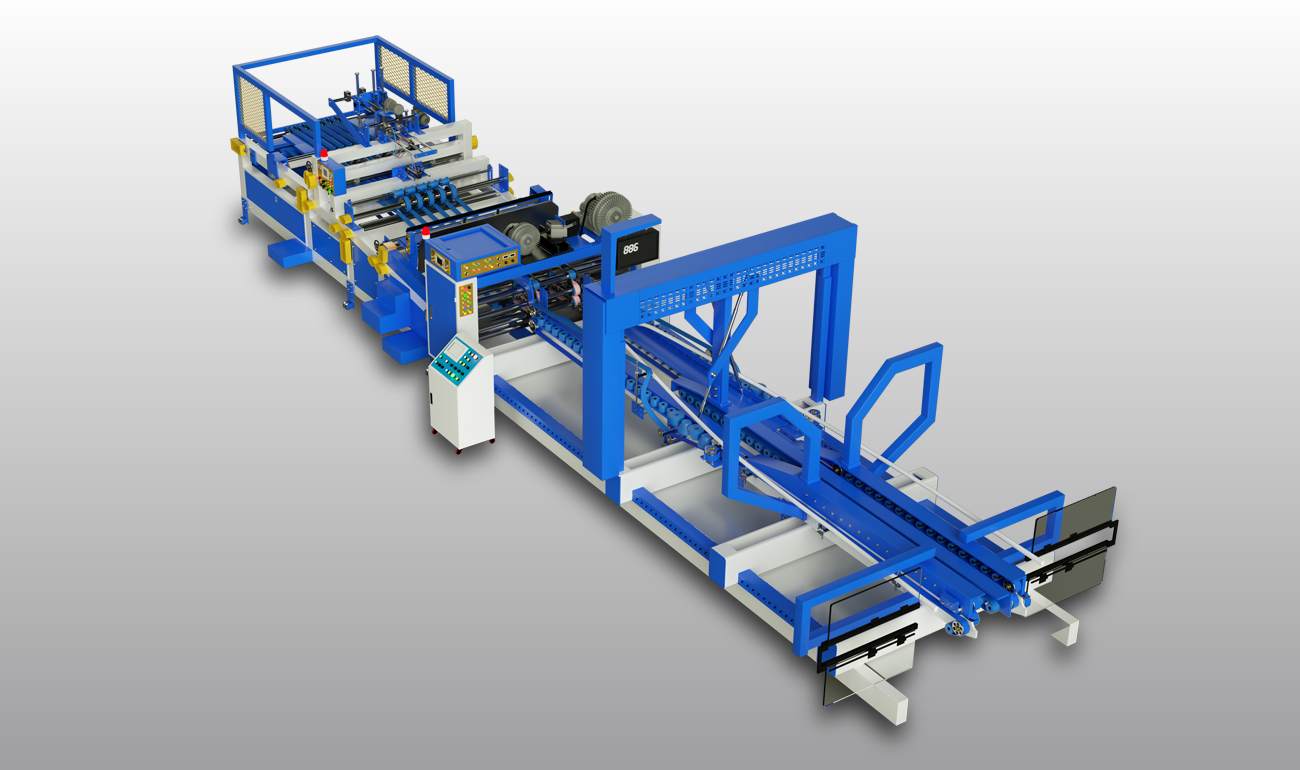

Machine Type |

Automatic Folder Gluer and Stitcher Machine |

|

Origin |

Completely designed and made in Korea |

|

Production Experience |

40 years of professional production experience |

|

Sales Volume |

More than 600 units sold |

|

Function and Configuration |

Multiple functions and configurations, customizable according to customer orders |

|

Feeding System |

Particular feeding system with no influence on carton compressive strength |

|

Stitching Feature |

Flat wire cut - in obliquely, strong penetration, stitcher thickness 0.5mm, good shape, no indentation when stacked |

|

Stack Design |

Two - times stack design to control gluer scissors - mouth error and improve paste - box speed |

EN