Frequently Asked Questions (FAQs) – Bottom Printing Top Cutting

1. What is a bottom printing top cutting machine?

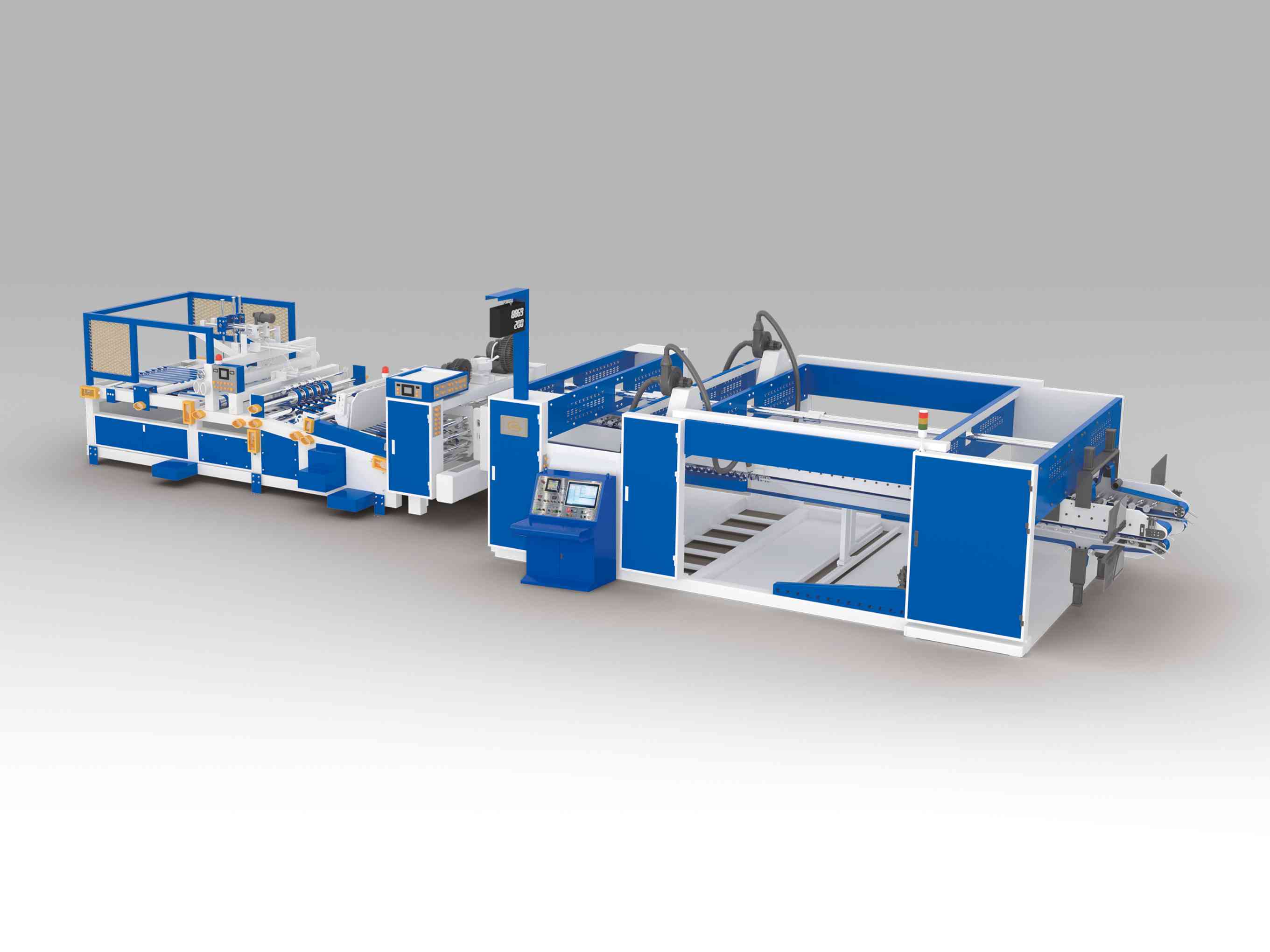

It is a corrugated box production machine where the flexographic printing unit is positioned below and the rotary die cutter above. This design ensures stable board feeding, accurate printing, and precise die cutting.

2. What are the main advantages of the bottom printing top cutting configuration?

- Better board stability during printing, especially for thin or warped corrugated sheets.

- Improved print registration and ink coverage.

- High-precision die cutting with minimal distortion.

- Ideal for high-volume production and custom packaging.

3. What types of corrugated boxes can this machine produce?

Giant's bottom printing top cutting machines can produce regular slotted cartons (RSC), die-cut boxes, e-commerce packaging, and custom printed cartons. They are suitable for both small batch and high-volume orders.

4. Can the machine handle both single-wall and double-wall corrugated boards?

Yes. The system is designed to accommodate different board thicknesses, from lightweight to heavy-duty corrugated sheets, ensuring consistent performance across materials.

5. Is this machine compatible with folder gluer and counter ejector systems?

Absolutely. Giant's bottom printing top cutting machines can be seamlessly integrated with folder gluer and counter ejector systems, allowing automated folding, gluing or stitching, and stacking of finished boxes.

6. How does this machine improve print accuracy?

By positioning the printing unit at the bottom, the board remains flat and stable during printing. This reduces warping, ensures consistent ink coverage, and delivers professional-grade registration.

7. Is the machine suitable for high-volume production?

Yes. The bottom printing top cutting configuration is optimized for continuous, high-speed operation, making it ideal for factories with large-scale box production needs.

8. Can this machine produce custom printed designs?

Yes. With precise flexo printing and die-cutting capabilities, it can handle multi-color printing, custom artwork, and complex box designs for branding and e-commerce packaging.

9. What type of maintenance is required?

Routine maintenance includes cleaning ink systems, lubricating moving parts, and checking die-cutting blades. Giant provides detailed manuals and technical support to ensure smooth, long-term operation.

10. Why choose Giant for bottom printing top cutting machines?

Giant offers decades of experience in corrugated box machinery, providing reliable, durable, and customizable solutions. Our machines are trusted globally for their precision, automation capability, and proven performance.

11. Can Giant customize the machine for specific production requirements?

Yes. Giant provides tailor-made configurations to meet unique workflow, board type, box size, and production volume requirements, ensuring maximum efficiency and return on investment.

12. Does Giant provide after-sales support?

Yes. Giant offers technical support, installation assistance, spare parts supply, and maintenance guidance to ensure long-term machine performance and minimal downtime.