Frequently Asked Questions (FAQs) – Top Printing Bottom Cutting

1. What is a top printing bottom cutting machine?

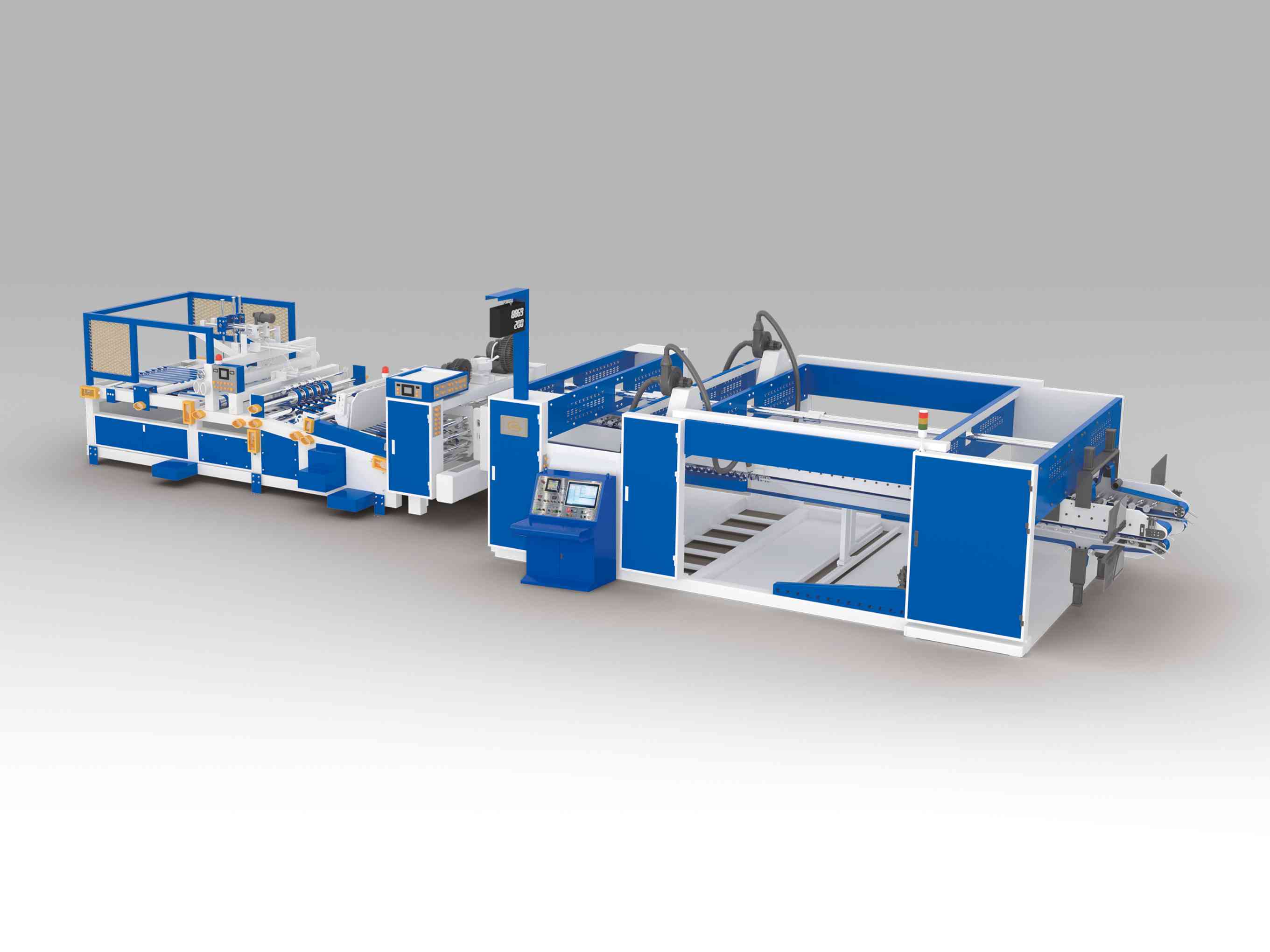

It is a corrugated box production machine where the flexographic printing unit is positioned on top and the rotary die cutter below. This ensures sharp print quality, accurate die cuts, and stable production for custom cartons and e-commerce packaging.

2. What are the main advantages of the top printing bottom cutting configuration?

- Superior print visibility and quality

- Easier access for plate mounting and maintenance

- Precise die cutting and slotting for complex box designs

- Reduced material deformation during processing

3. What types of boxes can this machine produce?

Giant's top printing bottom cutting machines are suitable for die-cut boxes, custom printed cartons, e-commerce packaging, RSC boxes, and specialty corrugated boxes.

4. How does this machine improve print alignment?

By separating the printing and cutting axes, the machine maintains board stability and minimizes distortion, ensuring consistent ink coverage and accurate registration for professional-quality packaging.

5. Can the machine be integrated with folder gluer and counter ejector systems?

Yes. Giant's system can be seamlessly connected to folder gluer and counter ejector units, enabling automatic folding, gluing or stitching, stacking, and counting with minimal manual intervention.

6. Is this machine suitable for high-volume production?

Absolutely. The top printing bottom cutting line is designed for continuous, high-speed operation, making it ideal for large-scale manufacturing and high-output packaging lines.

7. Can it handle multi-color printing and custom designs?

Yes. The top flexo printing unit supports multi-color printing, allowing for vibrant, precise graphics on corrugated boards for branding, e-commerce, and retail packaging.

8. What types of corrugated boards can it process?

The machine is compatible with single-wall, double-wall, and specialty corrugated boards, including lightweight sheets and heavy-duty boards, ensuring versatility across various packaging applications.

9. How easy is it to operate and maintain?

The machine features a user-friendly touchscreen interface, servo-controlled systems, and memory save functions for repeat orders. Maintenance is simplified with easy access to the printing unit and die-cutting components.

10. Why choose Giant for top printing bottom cutting machines?

Giant provides durable, customizable, and high-precision machines backed by years of experience, global technical support, and long-term spare parts supply, ensuring reliable performance and ROI.

11. Can Giant customize the machine for specific production needs?

Yes. Giant offers tailor-made solutions based on your box types, production volume, workflow requirements, and corrugated board specifications to optimize efficiency and output.

12. Does Giant provide after-sales support?

Yes. Giant delivers technical support, installation guidance, and maintenance assistance to keep your top printing bottom cutting line running smoothly with minimal downtime.