In addition to our core converting and printing systems, Giant also provides a full range of auxiliary equipment to complete and optimize your corrugated box production line. These support machines—such as pre-feeders, rotary die cutters, vibrators, and hydraulic auto stackers—are essential for improving automation, reducing labor, and increasing overall plant efficiency.

Whether you're upgrading existing equipment or building a full-scale automated packaging line, Giant’s supplementary machines offer performance, durability, and seamless integration.

Our Auxiliary Equipment Range

Pre-Feeders

Pre-feeders help deliver sheets smoothly into the main machine, maintaining consistent feed rates and preventing misalignment or machine stoppages.

- Improves feeding accuracy and speed

- Reduces operator fatigue

- Enhances long-run stability

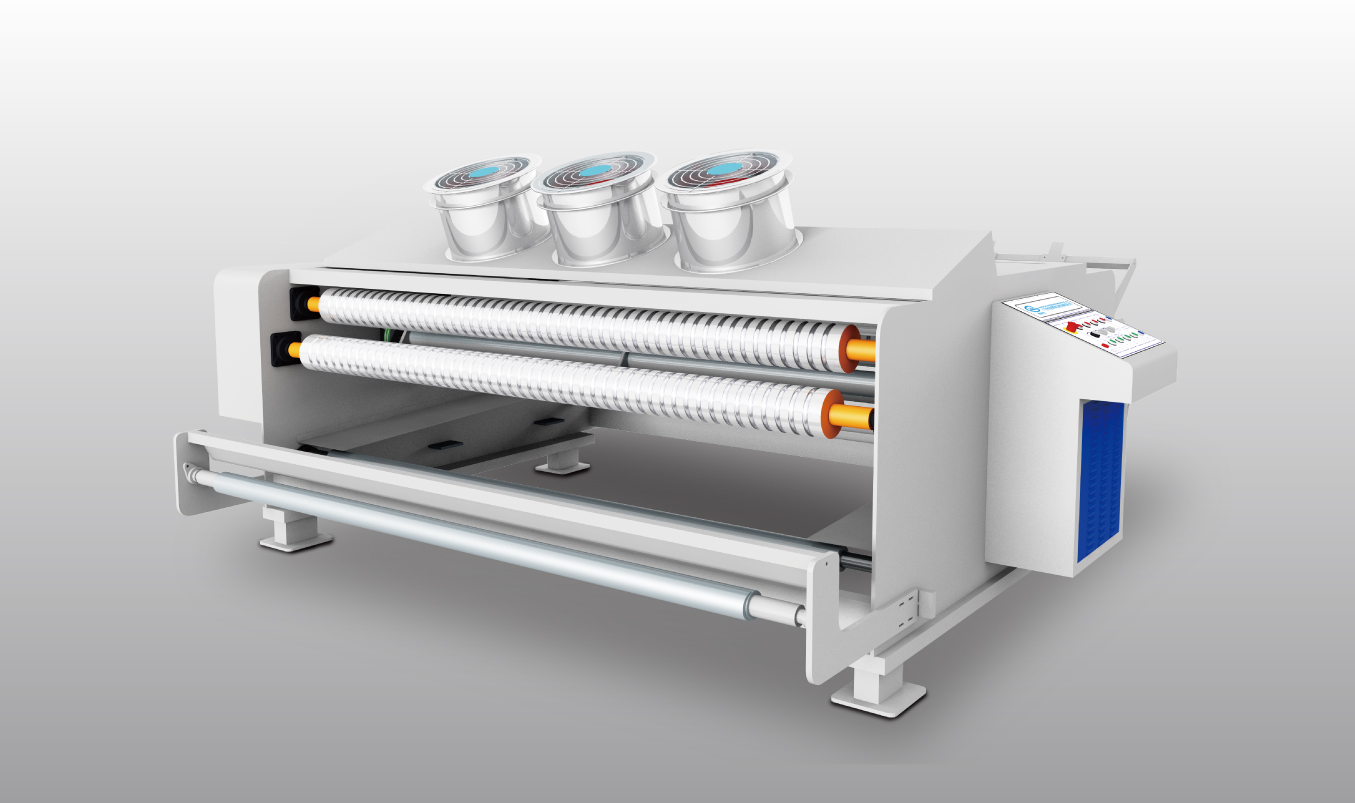

Rotary Die Cutter

Our rotary die cutter is built for precision shape cutting of corrugated sheets, suitable for producing custom box designs, displays, and ventilation holes.

- High-speed, inline cutting capability

- Compatible with multiple box types

- Durable steel and rubber anvil design

Vibrator

The vibrator unit is used after stacking or folding to help align and settle the corrugated boards into uniform stacks, ensuring neat bundling and easy strapping.

- Ideal for high-speed production lines

- Ensures box stack alignment

- Compact and efficient

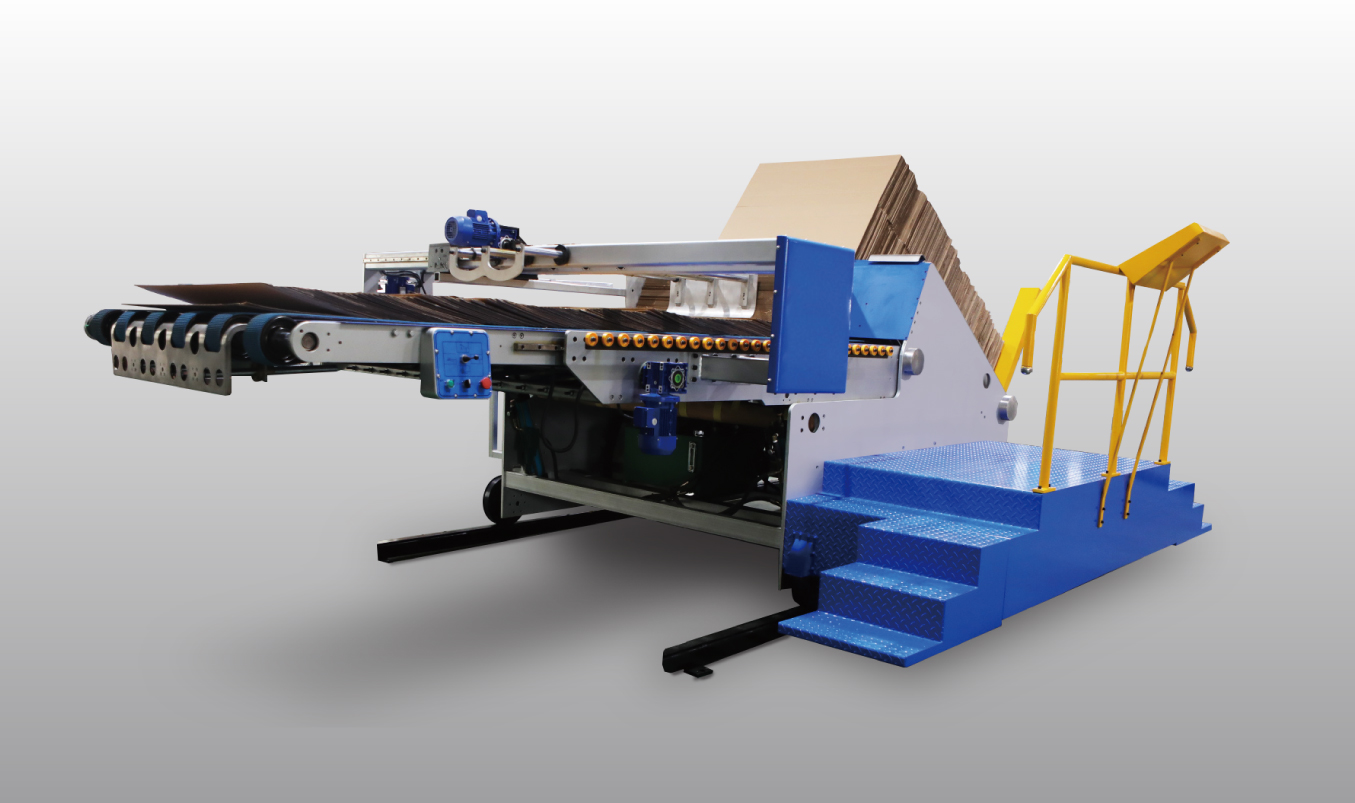

Hydraulic Auto Stacker

Our hydraulic auto stacker safely and efficiently stacks finished boxes for bundling, shipping, or further processing. It integrates well with folder gluers or die cutters.

- Fully automatic lifting and stacking

- Adjustable for various box sizes

- Safe, stable, and operator-friendly design

Why Choose Giant for Corrugated Machinery?

Giant is more than a machine provider—we are your long-term production partner. All of our auxiliary machines are:

- Designed for compatibility with Giant and other standard production lines

- Built with high-quality components for durability and long service life

- Backed by experienced engineers and responsive customer support

By integrating our auxiliary solutions, packaging manufacturers can achieve greater automation and productivity across the entire line—from sheet feeding to final stacking.