How to Choose the Best Corrugated Carton Machine for Your Packaging Needs

Choosing the best corrugated carton machine in 2025 is a crucial step for any packaging business that wants to boost productivity, reduce costs, and deliver high-quality cartons. These machines—also called corrugated box making machines, carton forming equipment, or carton production lines—come with different levels of automation, functions, and production capacities.

In this updated guide, you'll discover the key factors to consider before investing, including production volume, box styles, automation levels, and cost. We'll also explain why Giant corrugated carton machines, trusted by manufacturers worldwide, are a reliable choice for packaging businesses looking to scale efficiently.

Understanding Packaging Needs Before Choosing a Corrugated Carton Machine

The first step in choosing the best corrugated carton machine is to analyze your production needs:

Production Volume and Output Capacity: Are you producing small batches or large-scale orders? Machines range from semi-automatic models suitable for low to medium output, to fully automatic corrugated box making lines designed for high-volume production. Matching machine capacity with your demand avoids underperformance or unnecessary expenses.

Box Types, Sizes, and Flute Profiles: Different packaging applications require various corrugated board types (single wall, double wall, triple wall) and flute profiles (A, B, C, E, F flutes). Your machine should support the range of box sizes and styles you plan to manufacture, including die-cut, regular slotted containers (RSC), or specialty boxes.

Material Compatibility With Corrugated Sheets: Ensure the machine can handle the thickness and quality of corrugated sheets you use, whether recycled or virgin fiber boards.

Key Features of Corrugated Carton Machines (Box Making, Printing, Folding, Gluing)

Automation Level and Workflow Integration

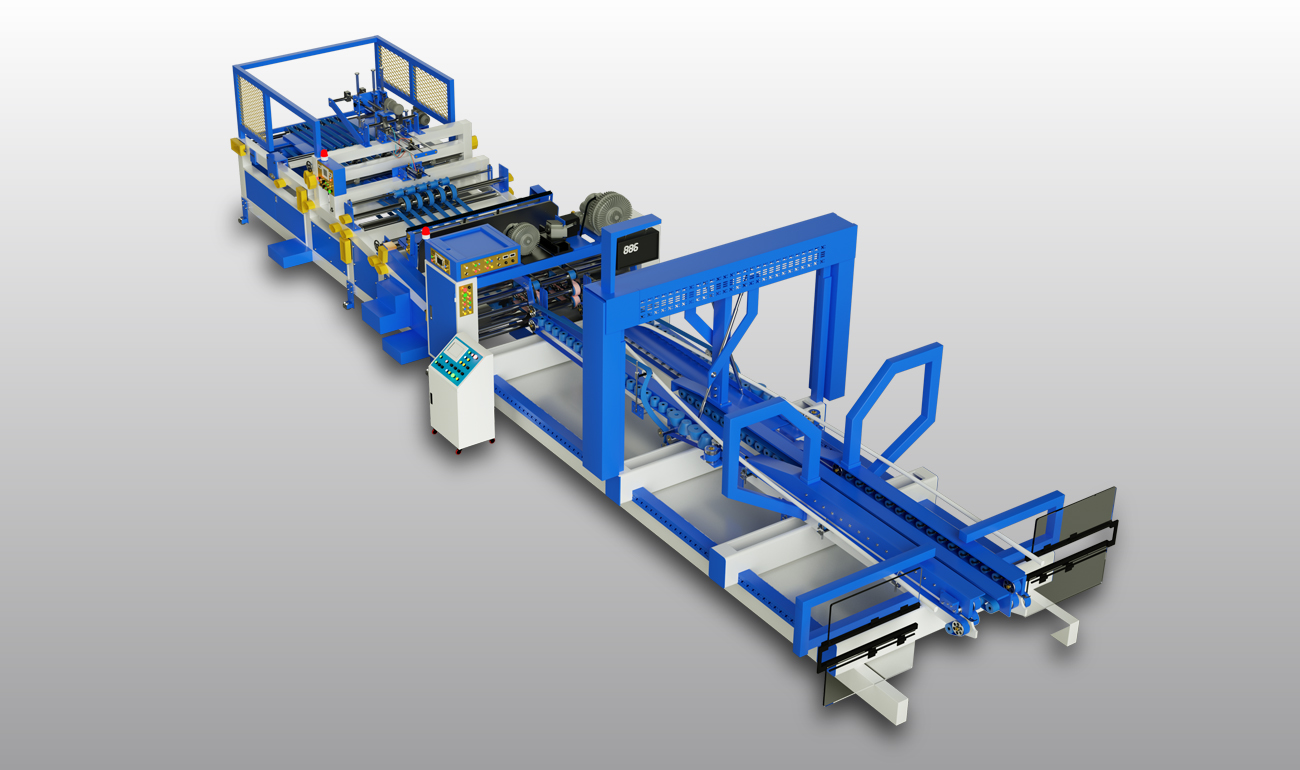

Corrugated carton machines vary in automation from manually operated slotters and flexo printers to fully integrated production lines combining printing, slotting, die-cutting, folding, gluing, and stacking. Higher automation reduces labor costs, increases speed, and improves consistency. For example, fully automatic corrugated box making machines with programmable controls enable quick job changes and precise cutting, ideal for businesses with diverse packaging needs.

Multi-Functionality: Printing, Slotting, and Die-Cutting

Machines that combine multiple functions—such as flexographic printing, creasing, slotting, and die-cutting—help streamline production and reduce equipment footprint. These multi-functional corrugated board production lines improve efficiency and reduce handling errors.

Material Feeding and Handling Systems

Efficient feeding mechanisms, such as vacuum transfer systems, ensure smooth handling of corrugated sheets, minimizing jams and material waste. This is crucial for maintaining high-speed production and consistent quality.

Precision Printing and Quality Control with Anilox Rollers

Look for machines equipped with ceramic anilox rollers for high-quality printing, precision creasing and slotting tools, and automatic glue application systems. These features ensure your cartons have sharp prints, clean folds, and strong bonding, enhancing the overall product appearance and durability.

Energy Efficiency and Eco-Friendly Corrugated Production

Modern corrugated carton machines incorporate energy-saving motors and optimized processes to reduce power consumption and environmental impact. Choosing energy-efficient equipment supports sustainable manufacturing and lowers operating costs.

Maintenance, Spare Parts, and After-Sales Service

Reliable technical support, easy access to spare parts, and straightforward maintenance procedures are vital to minimize downtime. Partnering with a manufacturer known for excellent after-sales service ensures your packaging line remains productive.

Safety Standards and Ergonomic Design

Ensure the equipment complies with safety standards, including emergency stops, protective guards, and ergonomic design to protect operators and reduce workplace accidents.

Why Choose Giant Corrugated Carton Machines for Packaging Efficiency

Giant is a globally recognized manufacturer specializing in advanced corrugated carton machinery, leveraging Korean technology and innovation. Here's why Giant is a preferred partner for packaging manufacturers:

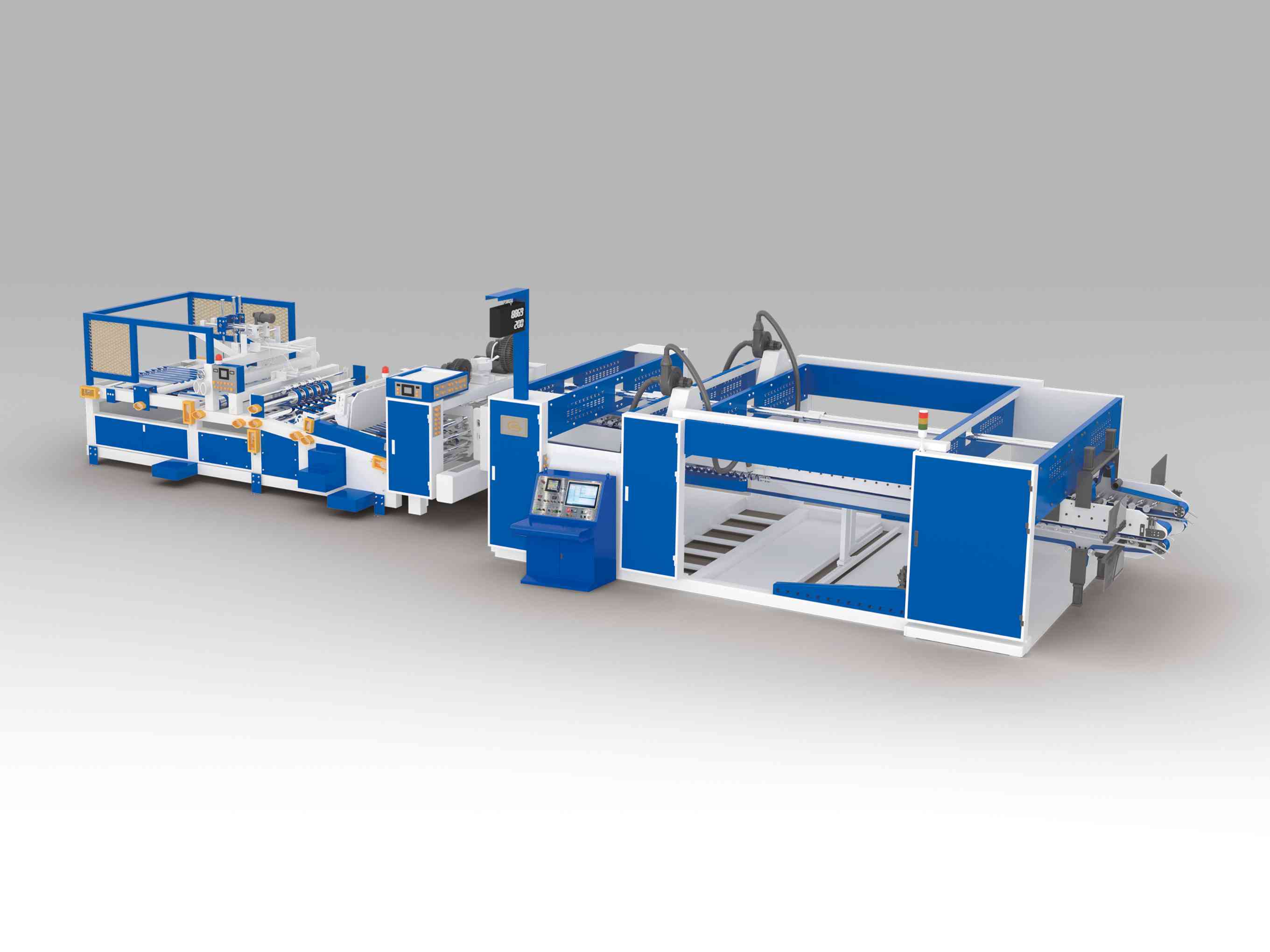

Wide Range of Box Making and Carton Forming Equipment: Giant offers a comprehensive lineup of corrugated box making machines, including flexo printer slotters, die-cutters, folder gluers, and complete production lines. Their equipment supports large sheet sizes (up to 1600 x 3200mm) and various flute types, accommodating diverse packaging requirements.

Dual Gluing and Stitching for Stronger Cartons: Giant machines feature unique dual gluing and stitching capabilities, enhancing box strength and durability—ideal for heavy-duty packaging and custom designs.

Advanced Material Handling: Equipped with vacuum transfer systems, Giant's corrugated board machinery ensures smooth, precise feeding, reducing waste and increasing production speed.

Superior Printing Quality: Using ceramic anilox rollers and advanced flexographic printing technology, Giant machines deliver sharp, vibrant prints on corrugated cartons, boosting brand visibility.

User-Friendly Operation: Giant's equipment includes automatic cleaning systems, adjustable feeding mechanisms, and intuitive controls, reducing operator fatigue and training time.

Global Presence and Support: With 80% of their machines exported worldwide—including markets in America, Mexico, Europe, and Asia—Giant provides reliable after-sales service and spare parts availability, ensuring minimal downtime.

Customization and Upgradability: Giant offers tailored solutions to upgrade existing corrugated carton machinery or design new production lines, ensuring your equipment perfectly fits your operational needs.

Additional Considerations When Selecting Corrugated Carton Machinery

Budget and ROI: While high-end, fully automated corrugated carton machines require significant investment, the long-term gains in efficiency, quality, and reduced labor costs often justify the expense. Balance your budget with your growth plans.

Industry Certifications: Machines certified for safety and quality standards ensure compliance with regulations and protect your workforce.

Future Expansion: Choose equipment that can be upgraded or expanded to accommodate increased production or new packaging styles.

Demonstrations and References: Request machine demonstrations and speak with existing users to gain insights into performance, reliability, and service quality.

Frequently Asked Questions About Corrugated Carton Machines

1. How much does a corrugated carton machine cost?

The cost varies depending on automation level and size. Semi-automatic machines can start from $20,000–$50,000, while fully automatic corrugated box making lines may range from $100,000 to several hundred thousand dollars.

2. What is the difference between semi-automatic and fully automatic carton machines?

Semi-automatic machines require more manual input and are suitable for small to medium orders. Fully automatic machines integrate printing, slotting, folding, and gluing, making them ideal for high-volume production.

3. Which industries use corrugated box making machines the most?

Corrugated carton machines are widely used in e-commerce, food & beverage, consumer goods, and industrial packaging.

4. How long does a corrugated carton machine last?

With proper maintenance, high-quality machines can operate for 10–15 years or more.

5. How can I maintain a corrugated carton machine?

Regular cleaning, lubrication, and timely replacement of wear parts are essential. Choosing a manufacturer with strong after-sales support, like Giant, ensures long-term reliability.

Conclusion: Investing in the Right Corrugated Carton Machine for 2025

Selecting the best corrugated carton machine, also referred to as a corrugated box making machine or carton forming equipment, is a strategic investment that directly impacts your packaging efficiency, product quality, and long-term profitability.

By analyzing your production needs, evaluating machine features, and partnering with a trusted supplier like Giant, you can secure equipment that grows with your business.

For packaging manufacturers seeking reliability, speed, and superior carton quality, Giant’s corrugated carton machines represent a smart, future-proof choice in 2025.