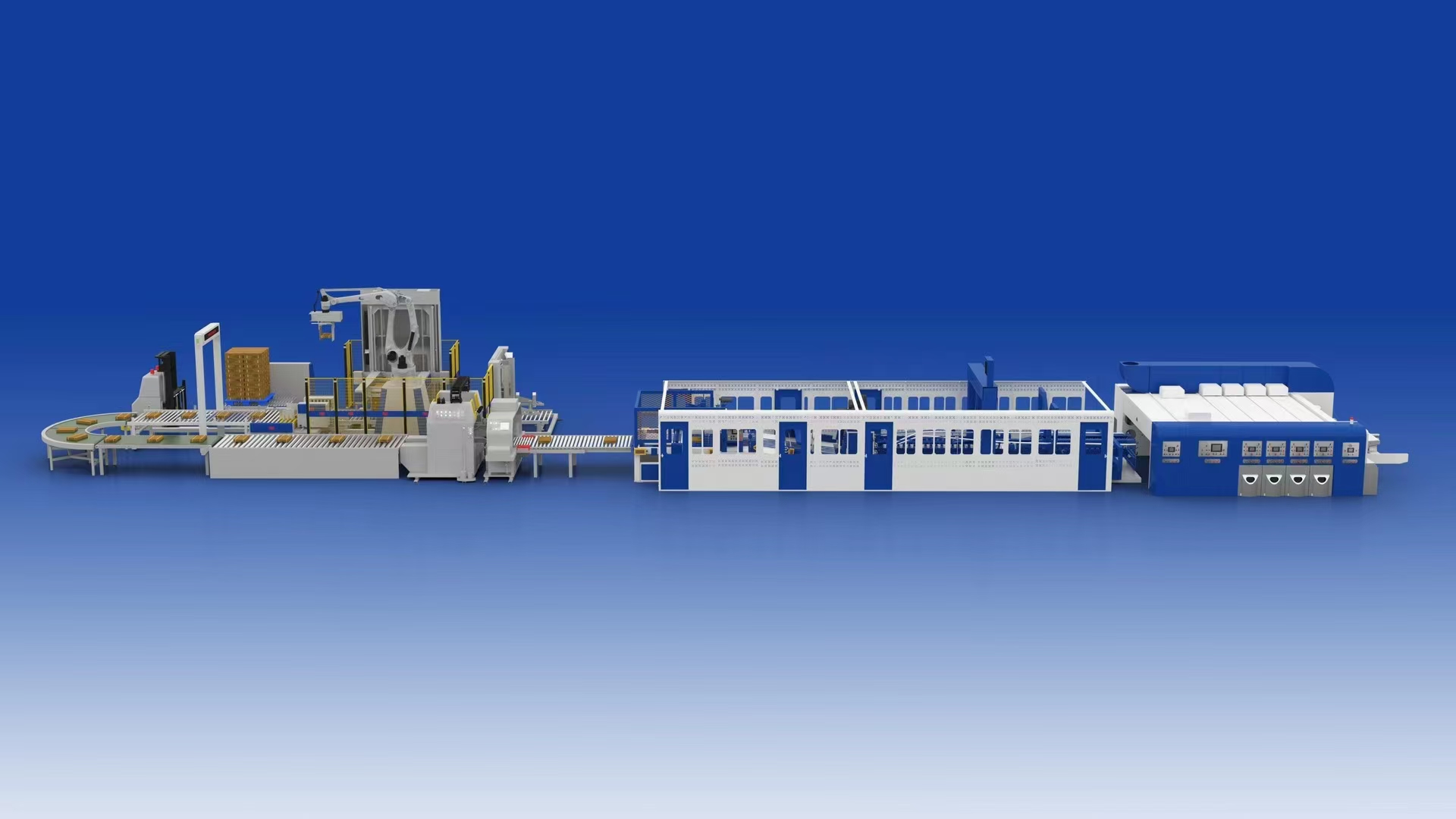

How to Choose the Right Flexo Printer Slotter Die Cutter Machine for Your Packaging Line

Learn how to select the best flexo printer slotter die cutter machine for corrugated packaging. Tips on speed, efficiency, and integrated solutions.

Learn how to select the best flexo printer slotter die cutter machine for corrugated packaging. Tips on speed, efficiency, and integrated solutions.

Solve common flexo printing issues on corrugated substrates. Learn tips for ink, substrate, plate, and registration with Giant's flexographic solutions.

Efficient pizza box printing with flexo technology. Learn key factors for ink, substrate, and machine setup — and why Giant's flexo press is ideal.

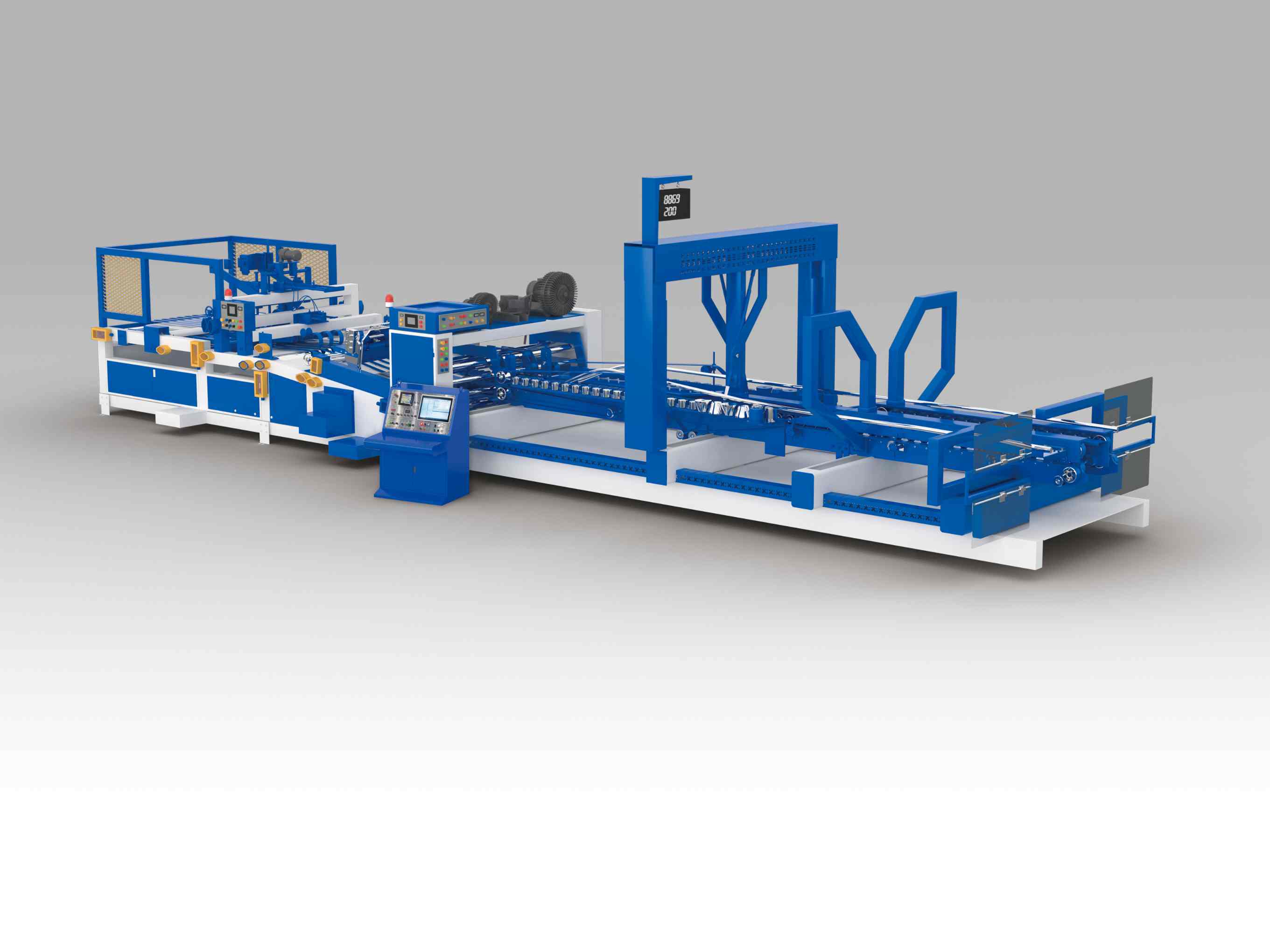

Corrugated slotter machines are vital in carton manufacturing. Giant provides efficient, durable slotter machines that boost packaging production and quality.

Corrugated box production relies on slotter and die cutting machines. Giant offers reliable equipment for high-speed, precise carton packaging.

Discover why flexographic printing is the best choice for carton packaging in 2025. Learn its advantages, applications, and why Giant is the top supplier.

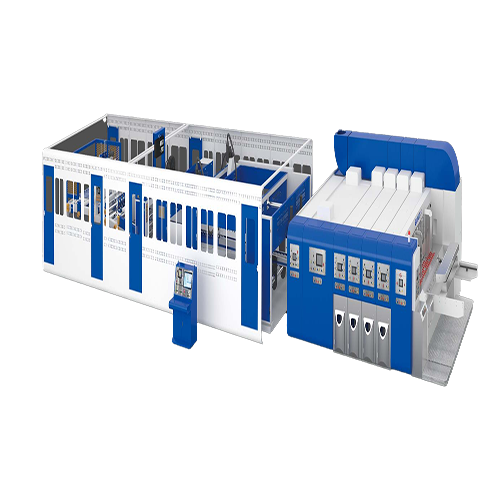

Discover how a flexo printer slotter die cutter works in 2025. Learn its functions, advantages, applications, and why choosing Giant can improve your packaging production efficiency.

Giant supplies advanced flexographic printing machines for corrugated cartons and pizza boxes. Achieve cost savings and consistent print quality.

Learn the top 10 features to look for in a modern flexo printing machine. Giant offers high-quality flexographic printers for pizza boxes, cartons, and food packaging.